Grouted Sock Anchor

A mechanical and grouted anchor system for stabilising structures such as retaining walls, embankments and bridge abutments.

Description:

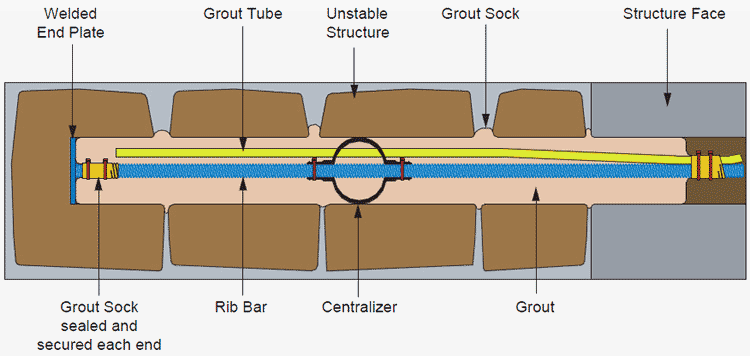

The grouted sock anchor system comprises of a high strength, stainless steel, ribbed bar, surrounded by a woven elastic polyester grout sock which is sealed at both ends.

The anchor is inserted into a pre-drilled hole in the structure to be stabilised and pressure grouted to form a strong mechanical and chemical reinforcement.

The grouted sock anchor, supplied to the specified length, is inserted into a pre-drilled core hole.

Grout is injected into the grout sock through the grout tube at approximately 2.5 bar. The sock acts as a temporary shutter whist it expands to tightly fit the contours of the core hole and local voids and fissures.

The properties of the woven fabric allow liquid to pass through the sock, further filling voids and forming a chemical bond with the surrounding structure. When cured, the grout and ribbed bar become a permanent integral part of the structure adding stability, rigidity and strength.

The end of the bar can be left uncovered for proof testing equipment or to attach load bearing plates. Alternatively the hole can be plugged with original material or concealed using a matching repair mortar such as Jahn M70.

Product Specifications

Mechanical Properties of Ribbed Bar

- Material

- Stainless Steel 304 S31

- Ultimate tensile stress

- 750N/mm2

- 0.2% yield stress (minimum)

- 650N/mm2

- Minimum elongation

- 15%

- Typical lengths

- 6m

- Straightness

- 2 in 1000

RB12 Performance Characteristics

- Nominal Diameter (mm)

- 12

- C.S.A. (mm²)

- 91

- 0.2% proof load (kN)

- 54

- Ultimate Tensile Load (kN)

- 64

- Weight/m (kg)

- 0.73

- Torque to develop 0.15% UTS (Nm)

- 40