Description:

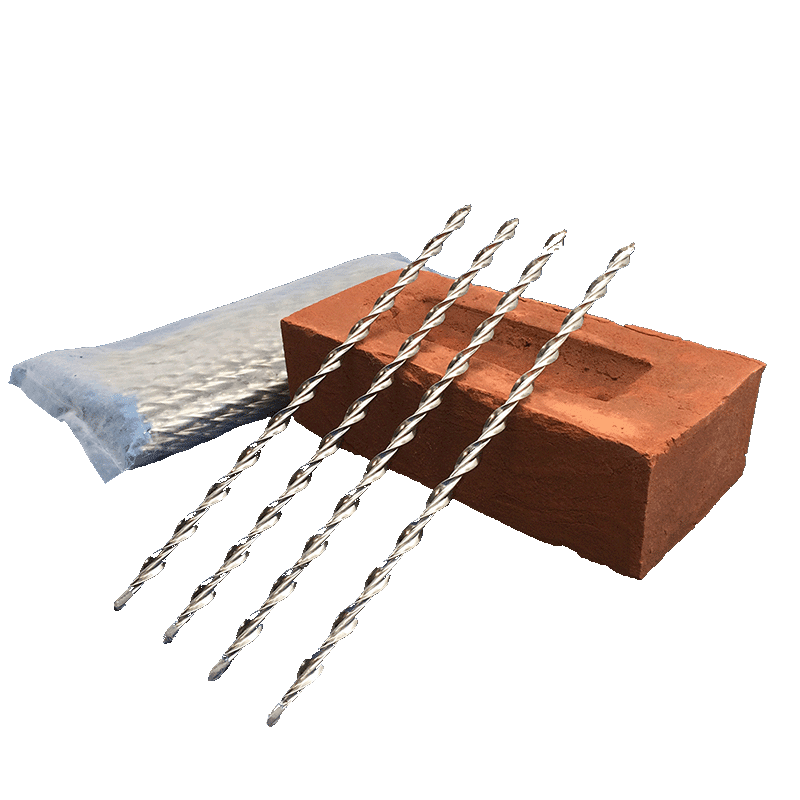

Thor Helical Retrofit Helical Wall Ties are one-piece stainless steel ties with a circumscribed diameter of 8mm. Hammer-driven into small pilot holes, the remedial ties corkscrew into brick, block and concrete to deliver a mechanical fix that grips the wall on each side of the cavity.

The threaded interlock connection of the self-tapping helical wall tie exerts no expansive stress into the brickwork and will not loosen with vibration, unlike ties that have expanding mechanisms and only deliver point loadings.

- Wall Tie Replacement

- Pinning Masonry Arches

- Adding Lateral Restraint by tying brickwork into the ends of floor joists

- Securing Solid Walls of Double-leaf or Collar-jointed Construction

- Tying Rubble-filled Walls

- Lintel Repair

Benefits:

- Suitable for remedial use in all types of masonry

- Particularly useful where fire performance, low temperatures and material compatibility issues need to be overcome.

- Require no resin or grout bonding agents

- Cost effective tooling

More Information:

N.B. The tie-length guide above is based on traditional cavity walls with 110mm imperial bricks. Adjustments must be made for walls with 100mm metric bricks.

For inserting remedial wall ties you also need to buy:

- A Remedial Wall Tie Setting Tool – the tool spins around the end of the tie and delivers hammer blows to it.

- A 6mm x 360mm SDS drill bit (180-245mm ties), ensuring the pilot hole is 10mm longer than the tie so that it can be recessed. – Use a 7mm drill bit of appropriate length for tying into engineering bricks or structural grade concrete – Use a 5mm pilot hole for perforated brickwork

Thor Helical remedial wall ties are suitable for use in all wall types. The 9mm remedial wall ties have European CE Mark Approval in respect of EN845-1:2013+A1:2007 for use in a wide variety of masonry materials.

Ties are packed in bags of 50.

Product Specifications

Mechanical Properties

- Material - Stainless Steel Grade

- AISI 304

- Ultimate Tensile Strength Rm (N/mm2)

- 1153.8

- Yield Strength - Rp0.2 (N/mm2)

- 1038.4

- Elongation - A(%)

- 4.8

- Ultimate Tensile Load Fm(kN)

- 12.2

Spec. acc. to EN 10270-3

Cold Formed