Waterproofing With a Trafficable Wear Layer

Resiplast Polyac® System for Waterproofing With a Trafficable Wear Layer

Ideal for applications on car park decks, bridges, cycle paths, platforms etc

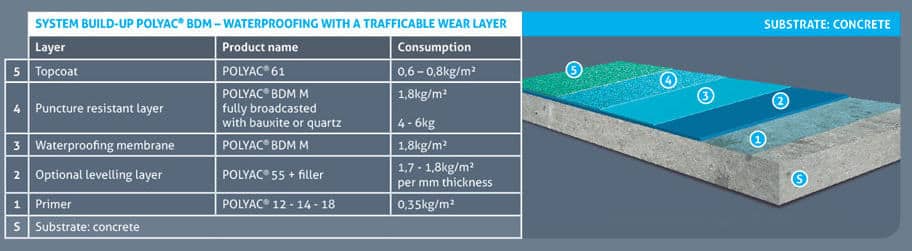

Concrete

- Primer – Polyac 12, Polyac 14, Polyac 18

- Optional levelling layer – Polyac 55

- Waterproofing Membrane – Polyac BDM-M

- Puncture Resistant Layer – Polyac BDM-M fully broadcast with bauxite or quartz

- Topcoat – Polyac 61

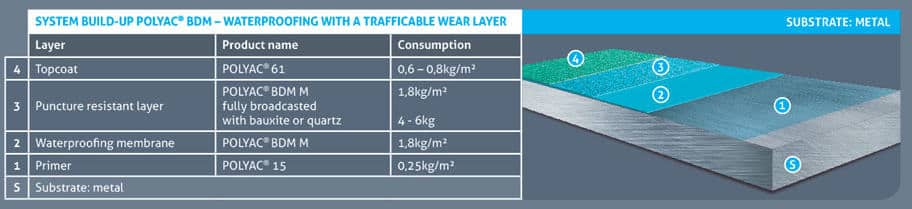

Metal

- Primer – Polyac 15

- Waterproofing Membrane – Polyac BDM-M

- Puncture Resistant Layer – Polyac BDM-M fully broadcast with bauxite or quartz

- Topcoat – Polyac 61

The system starts with the appropriate primer for the substrate.

For rough surfaces such as textured concrete or damaged asphalt a levelling layer of Polyac 55 can be used.

A waterproofing layer of Polyac BDM-M should then be applied. This will be white or colourless.

After approximately an hour, depending on the ambient temperature and the amount of catalyst used, a second layer of Polyac BDM-M should be applied and broadcast with quartz or bauxite. The provides the anti-skid, trafficable wear layer.

The colour of the 2nd layer should always be different to that of the 1st layer. This is necessary to guarantee complete coverage of the 1st layer during installation. This will also give you the ability to check over time that the wear layer has not worn off or to determine that the waterproofing layer is still intact and has not been mechanically damaged.

After inspection, the damage can be assessed and any localized repairs can be carried out quite easily. This is all thanks to the unlimited “re-coat” time of the entire system.

The entire system should then be covered with a topcoat. Polyac 61 is a watertight topcoat with excellent adhesion, high mechanical and wear resistance.

Polyac® 14 Primer Technical Data Sheet

Polyac® 14 Primer Technical Data Sheet  Polyac® 18 Primer Technical Data Sheet

Polyac® 18 Primer Technical Data Sheet  Polyac® BDM-M Technical Data Sheet

Polyac® BDM-M Technical Data Sheet  Polyac® 61 Technical Data Sheet

Polyac® 61 Technical Data Sheet  Polyac® 65 Technical Data Sheet

Polyac® 65 Technical Data Sheet  Polyac® 55 Technical Data Sheet

Polyac® 55 Technical Data Sheet